Wind power lubrication equipment solutions

- Categories:Solution

- Author:

- Origin:

- Time of issue:2020-10-30

- Views:0

(Summary description)Kaitian intelligent centralized lubrication system has the working characteristics of "intelligence, timing, ration and high frequency". Matching with Kaitian waste oil collection system, it can effectively avoid the leakage of lubricating oil and the amount of oil injection is not scientific

Wind power lubrication equipment solutions

(Summary description)Kaitian intelligent centralized lubrication system has the working characteristics of "intelligence, timing, ration and high frequency". Matching with Kaitian waste oil collection system, it can effectively avoid the leakage of lubricating oil and the amount of oil injection is not scientific

- Categories:Solution

- Author:

- Origin:

- Time of issue:2020-10-30

- Views:0

The working characteristics of Kaitian intelligent centralized lubrication system are "intelligent, timing, quantitative and high frequency". When used together with Kaitian waste oil collection system, it can effectively avoid the problems of external leakage of lubricating oil, unscientific oil injection and inability to discharge waste grease, so that the lubricating parts are always in good lubrication state, so as to effectively prolong the service life of lubricating parts.

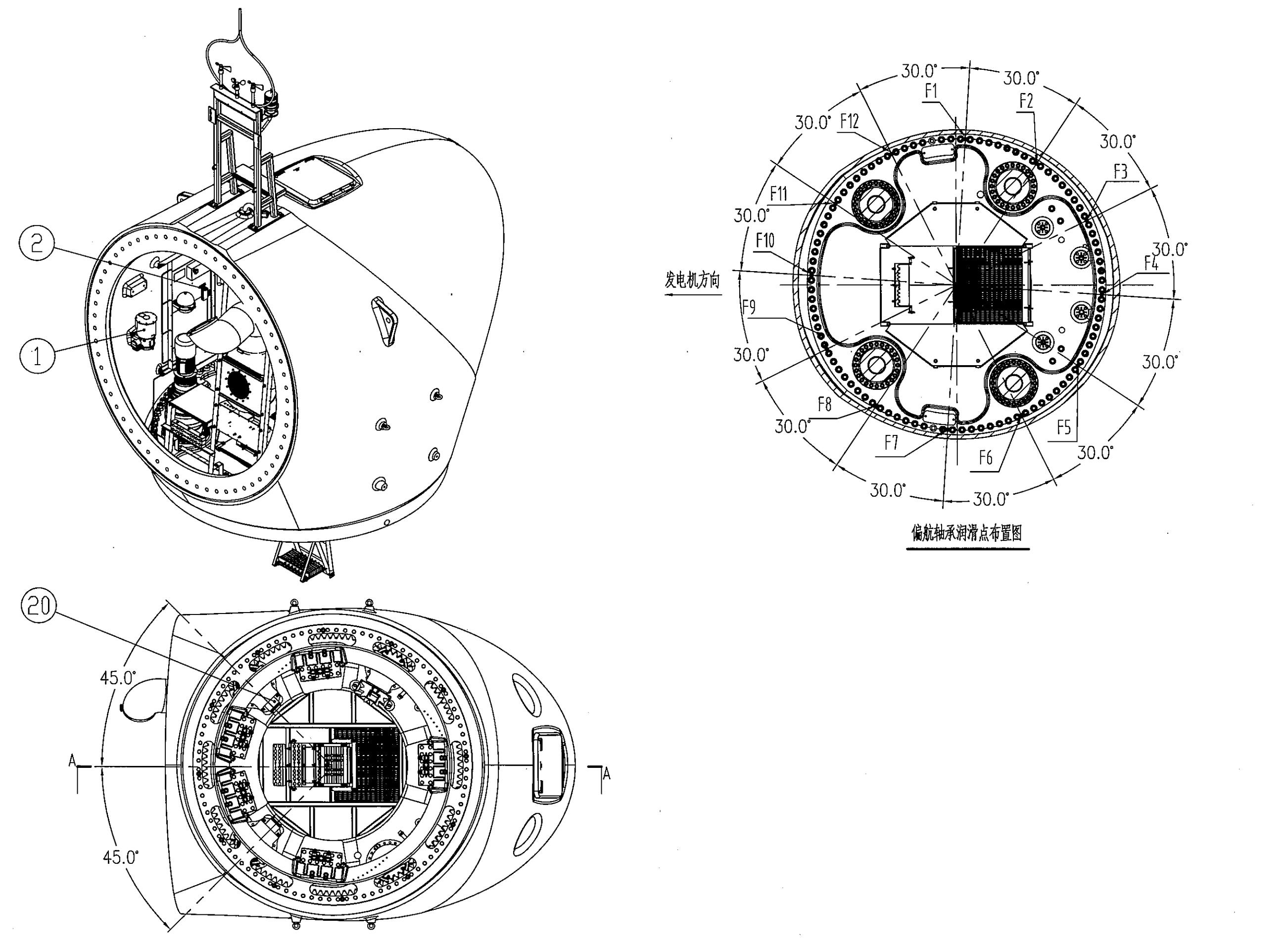

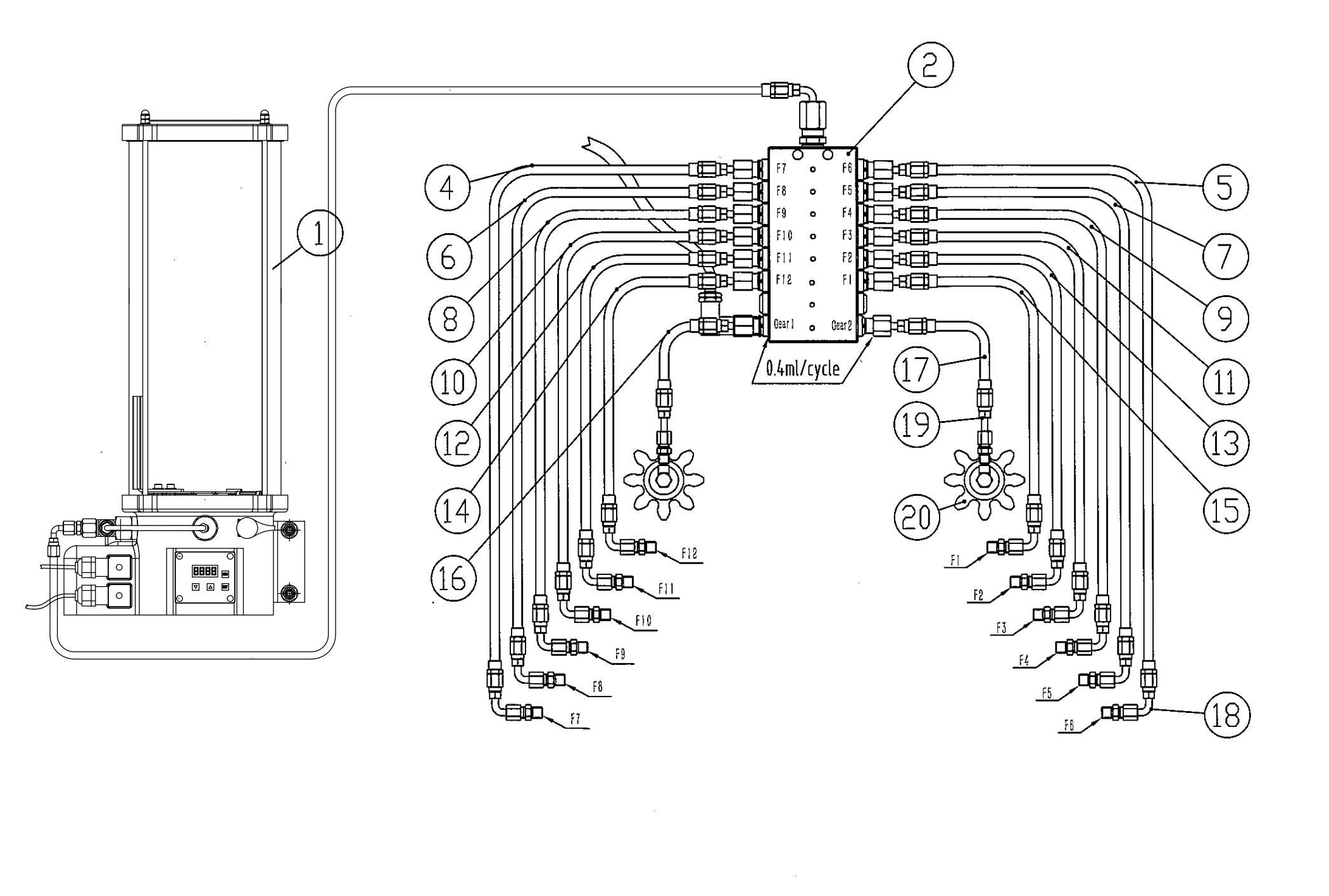

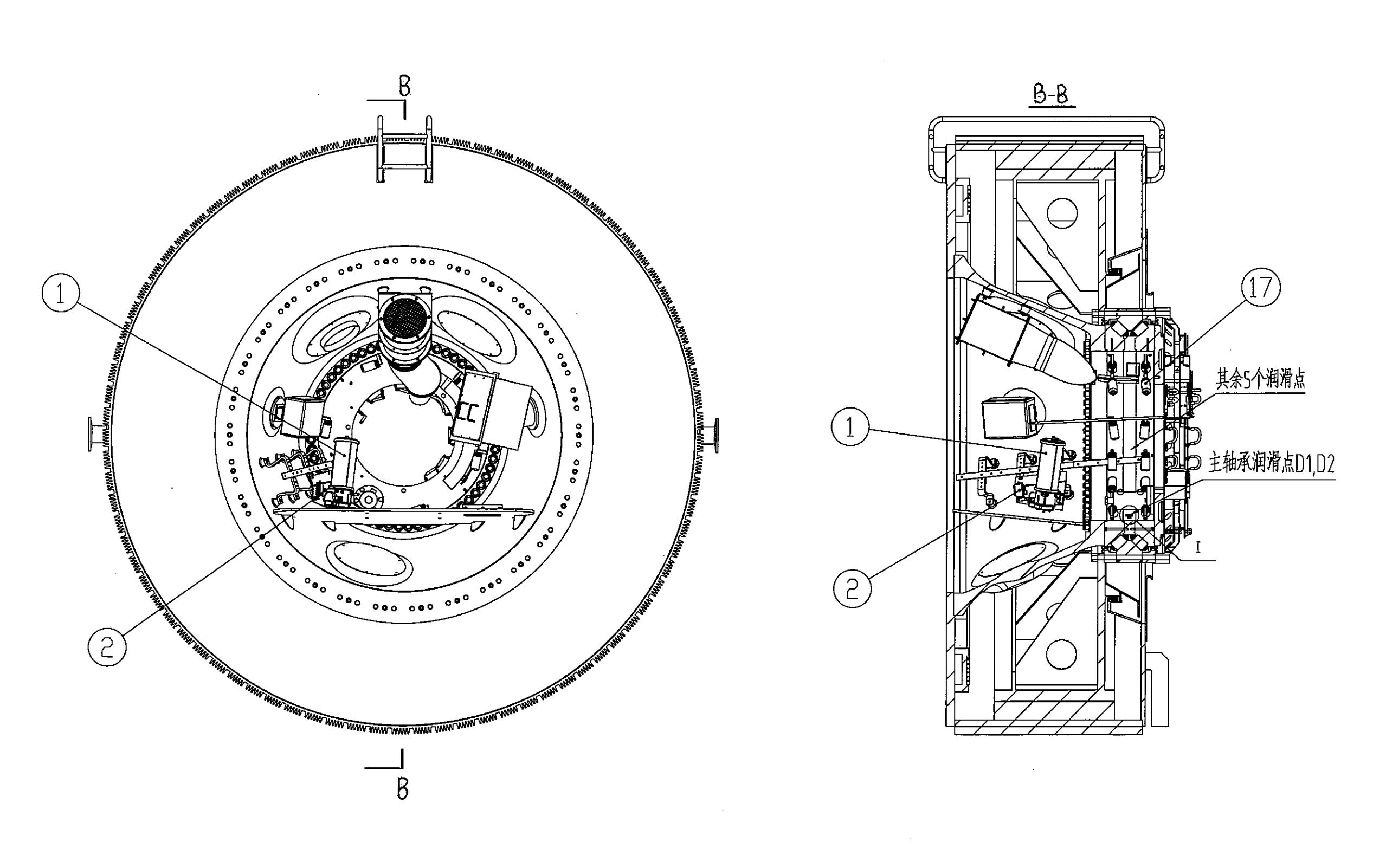

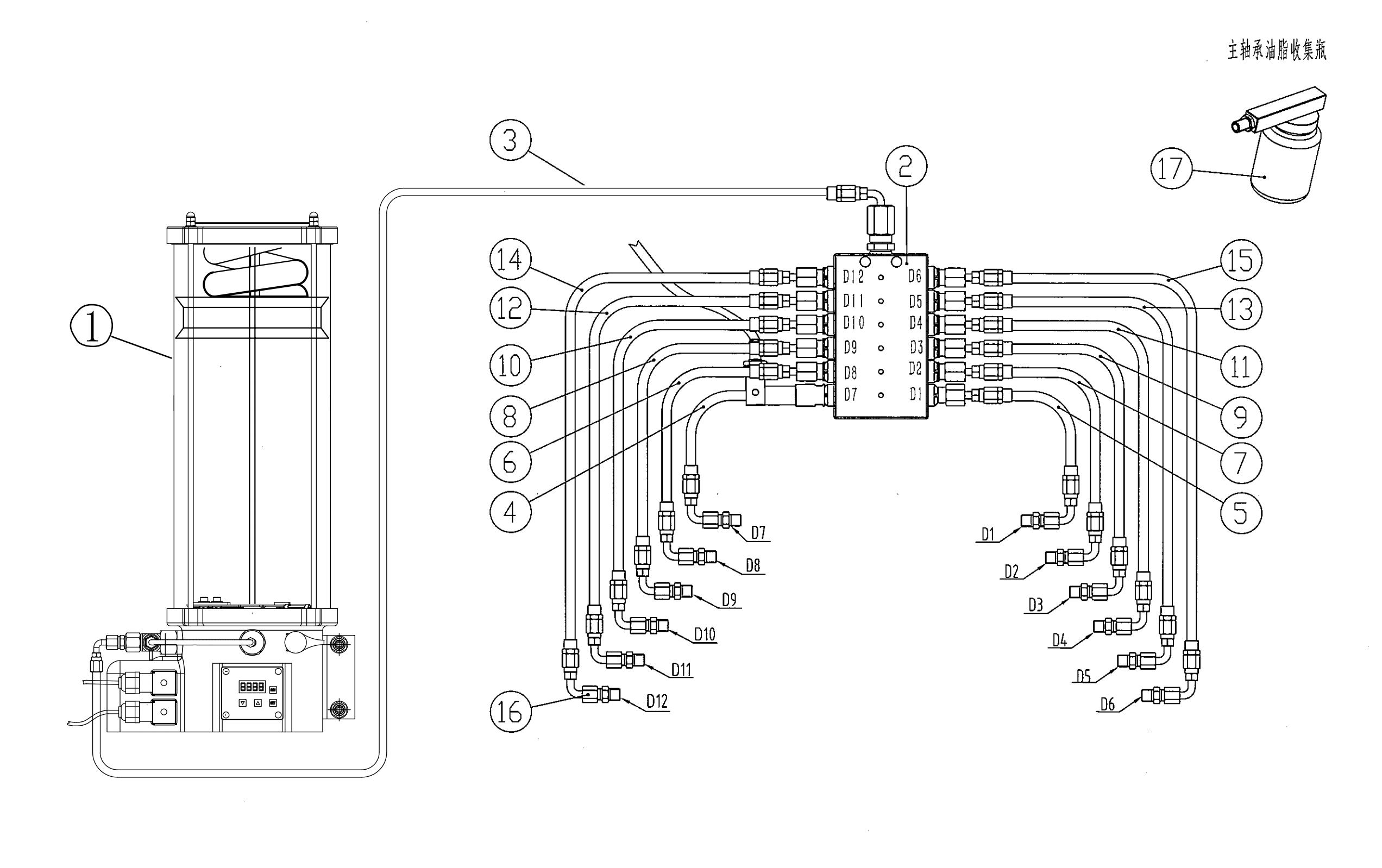

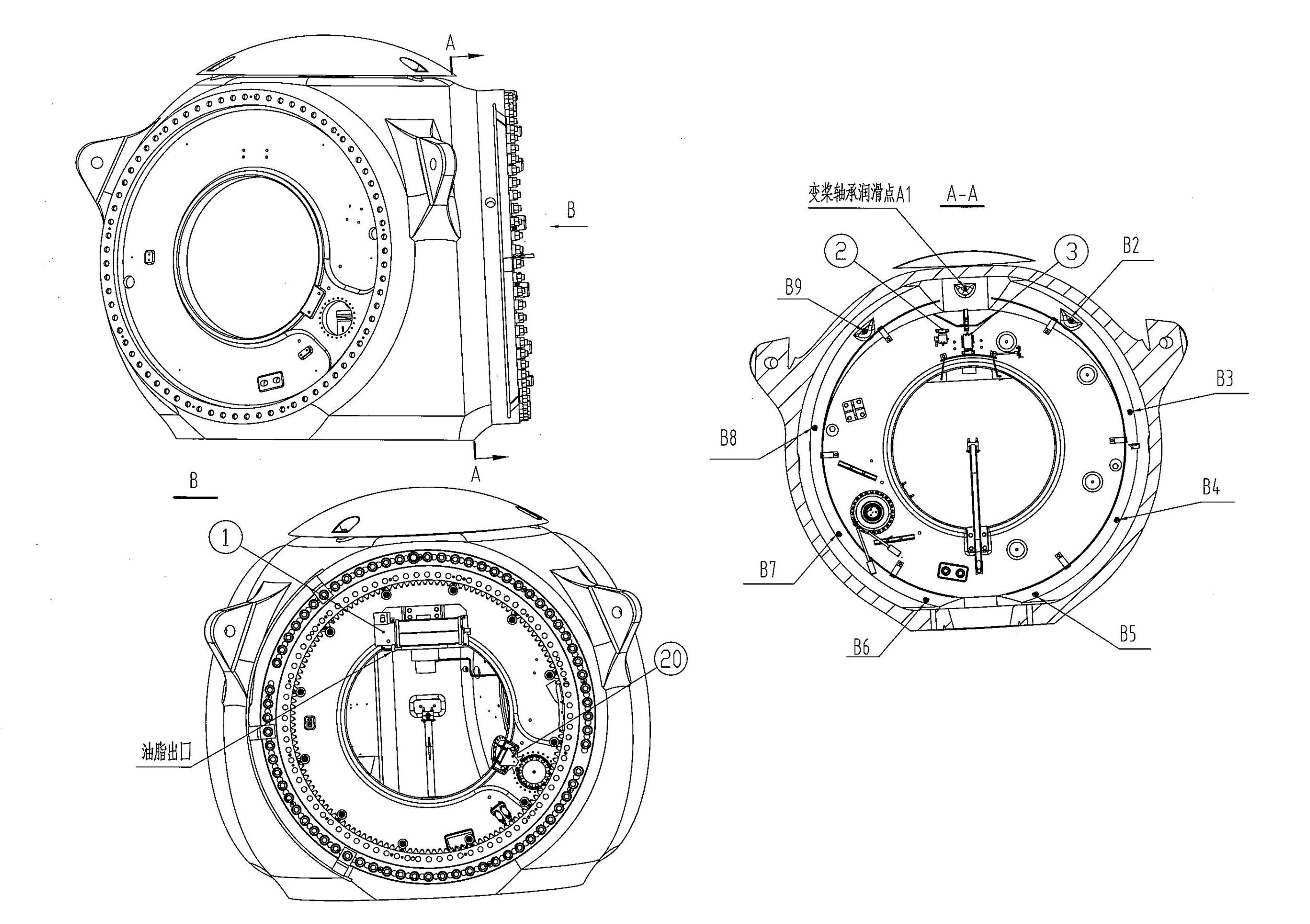

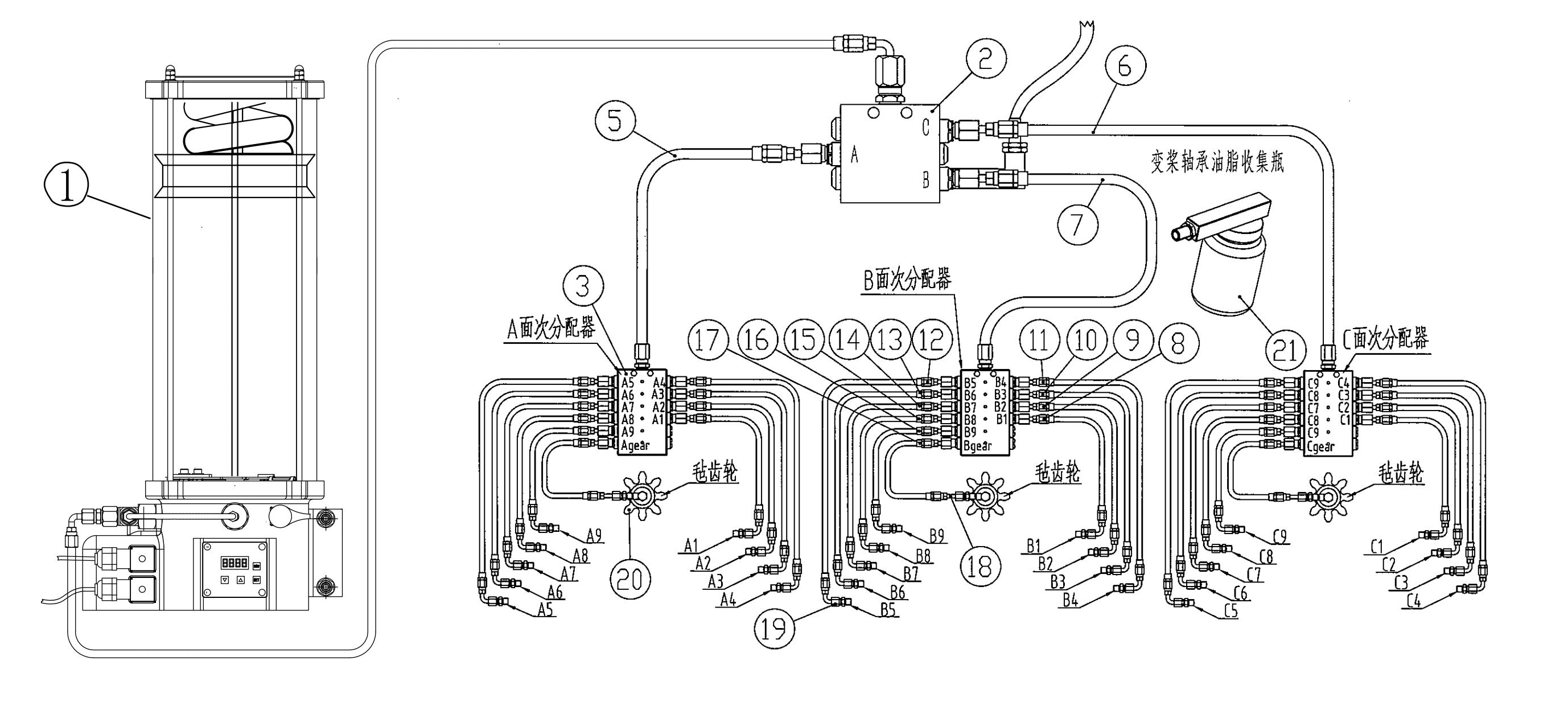

Schematic diagram of wind power generation lubrication system

Yaw bearing lubrication system

Spindle bearing lubrication system

Pitch bearing lubrication system

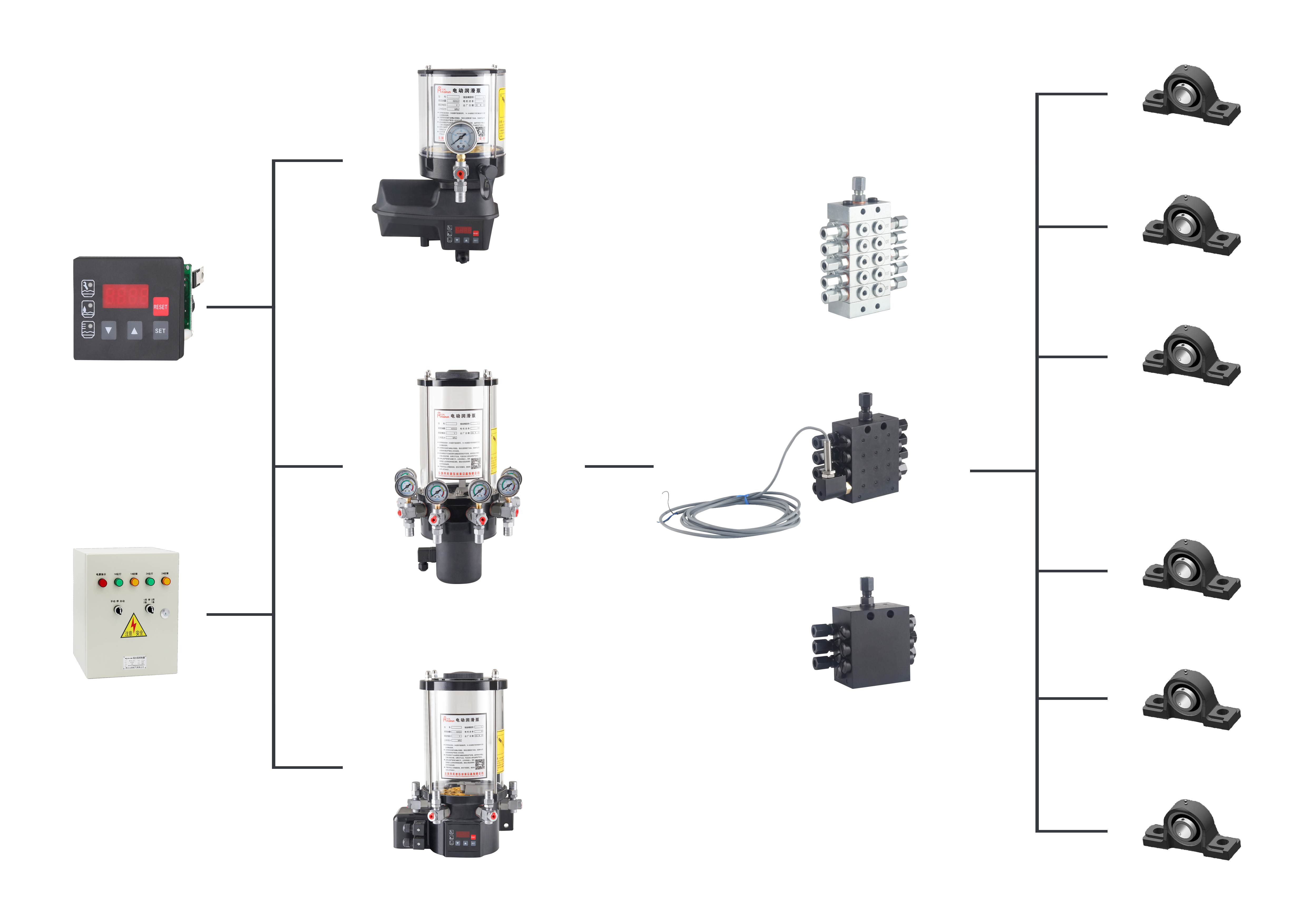

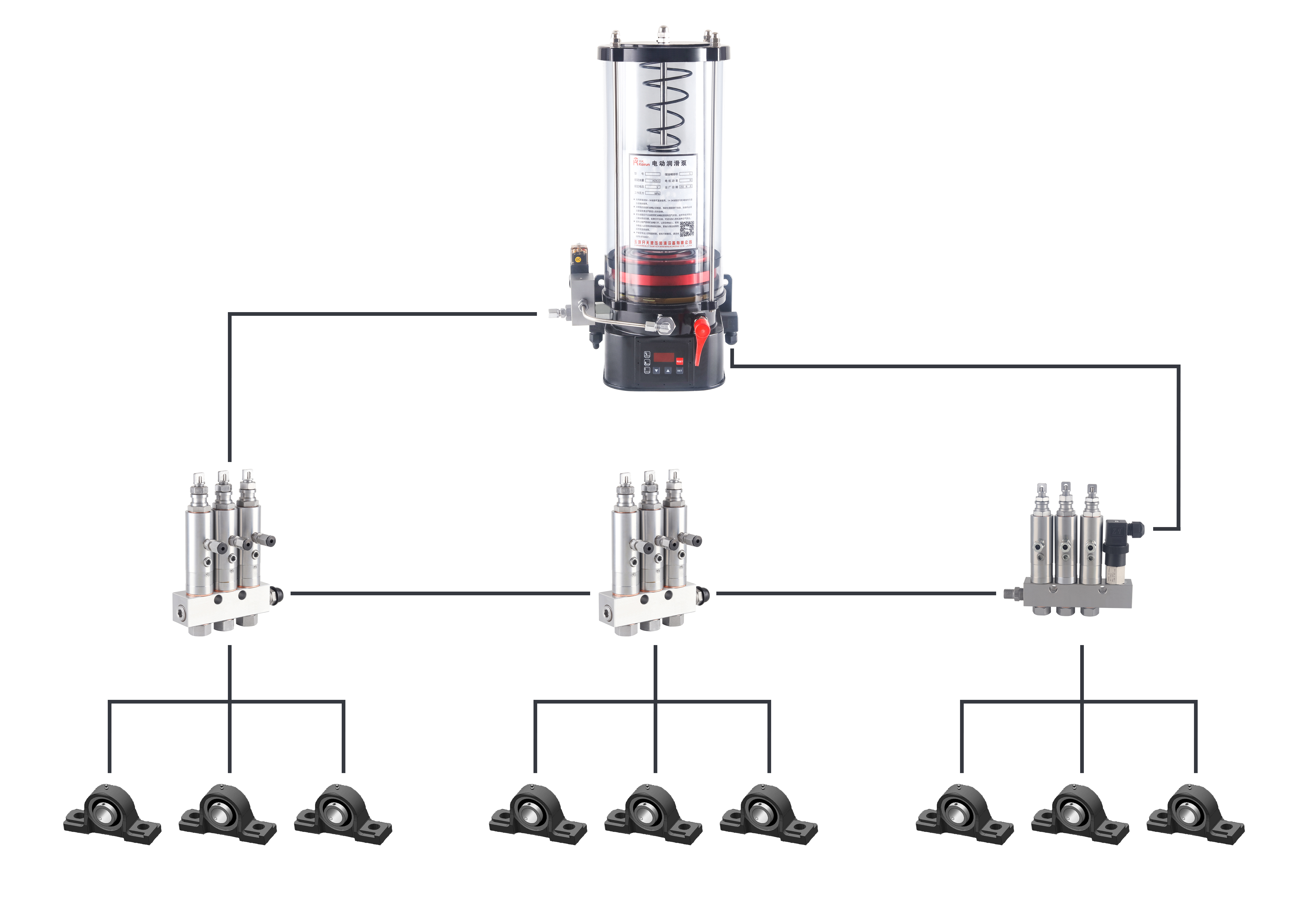

Progressive centralized lubrication system

The progressive centralized lubrication system is composed of electric lubrication pump, progressive distributor, pipeline accessories and control parts. The utility model is characterized in that the distributor transmits the lubricant to each lubrication point under the action of pump pressure. Its operating principle is based on reliable progressive work. The system can work under high pressure and quantitative gap, which enables the system to work normally under large temperature difference. The oil filling amount of the system is accurate. The oil filling amount depends on the internal plunger area and working stroke of the distributor, which is convenient for installation, adjustment and maintenance.

Integrated single line centralized lubrication system

The integrated single line centralized lubrication system is composed of plunger lubrication pump, integrated single line distributor, monitor, pressure relief valve, oil pressure sensor, main oil pipeline, oil distribution pipeline, harness and pipeline accessories. The plunger lubrication pump is respectively connected to each distributor group through the main oil pipeline, the oil pressure sensor is set at the end of the main oil pipeline, and the oil outlet of the distributor is connected to the corresponding lubrication point.

|

It may ensure turbine operation free of trouble and reduced unexpected shutdown Autol wind power centralized lubrication system is designed with smart central lubrication. Via system transmission port, it may realize remote lubrication on-line control and monitoring and perform on-line monitoring of system operating status while remotely modify the operating parameters of the lubrication system to ensure better bearing lubrication. Autol's waste grease collection system for wind farm may maximize bearing reliability and stability and operator's working safety in wheel hub. Smarter and more controllable bearing lubrication environment reduces damage to bearing and lose in output of power generation due to bad grease discharging, increases its service life, and reduces shutdown frequency and duration. |

| It simplifies services and prolongs system maintenance interval In order to ensure bearing good lubrication of wind farm, the waste grease in the internal bearing chamber must be removed. In a wind farm in Inner Mongolia in China, before the Autol's patent product Suplub-W automatic waste grease collection system was installed, the grease seal of pitch bearings of this wind power generator was heavily spilled. After this system has been in stable use for almost 9 months, the automatic waste grease collection system sucked waste grease from the bearing approximately equaled to the new grease filled into the bearing by the centralized lubrication system. After replacement, no grease spilled from the grease seal, avoiding pollution and increasing bearing service life. Autol waste grease collection system of wind farm is used with centralized lubrication system, causing better result of operation, cyclic operation at a fixed interval for several minutes each time. Correct centralized lubrication system may simplify services, prolong interval of system maintenance and protect equipment under various climate conditions. |

|

Scan the QR code to read on your phone

Add:No. 1, Building 45b, North Chuangrong Industrial City, Yucheng Sub-district, Yuhuan City, Zhejiang Province

Zip:317600

Tel:0576-87234521

Fax:0576-87234522

Contact person: Manager Zhao

Mobile phone no.:13967670889

Email:office@kaitianyeya.com

Web:www.kaitianyeya.com

Copyright © Yuhuan Kaitian Hydraulic Lubrication Equipment Co., Ltd. 浙ICP备16006032号 Power:300.cn